Glenoid Implant Optimization

Context & Objectives

Total shoulder arthroplasty is growing rapidly, with over 15,000 implants placed in France in 2024.

Glenoid loosening remains the most frequent complication, driven by poorly distributed stresses,

insufficient anchorage, or limited osteointegration.

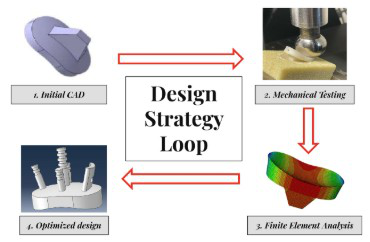

To guide our work, we carried out an extensive state‑of‑the‑art review, combining experimental studies and finite element models from the literature.

Objective: design a glenoid implant geometry with improved mechanical stability, supported by both simulation and experimental validation.

.webp)

Material Characterization & Mechanical Tests

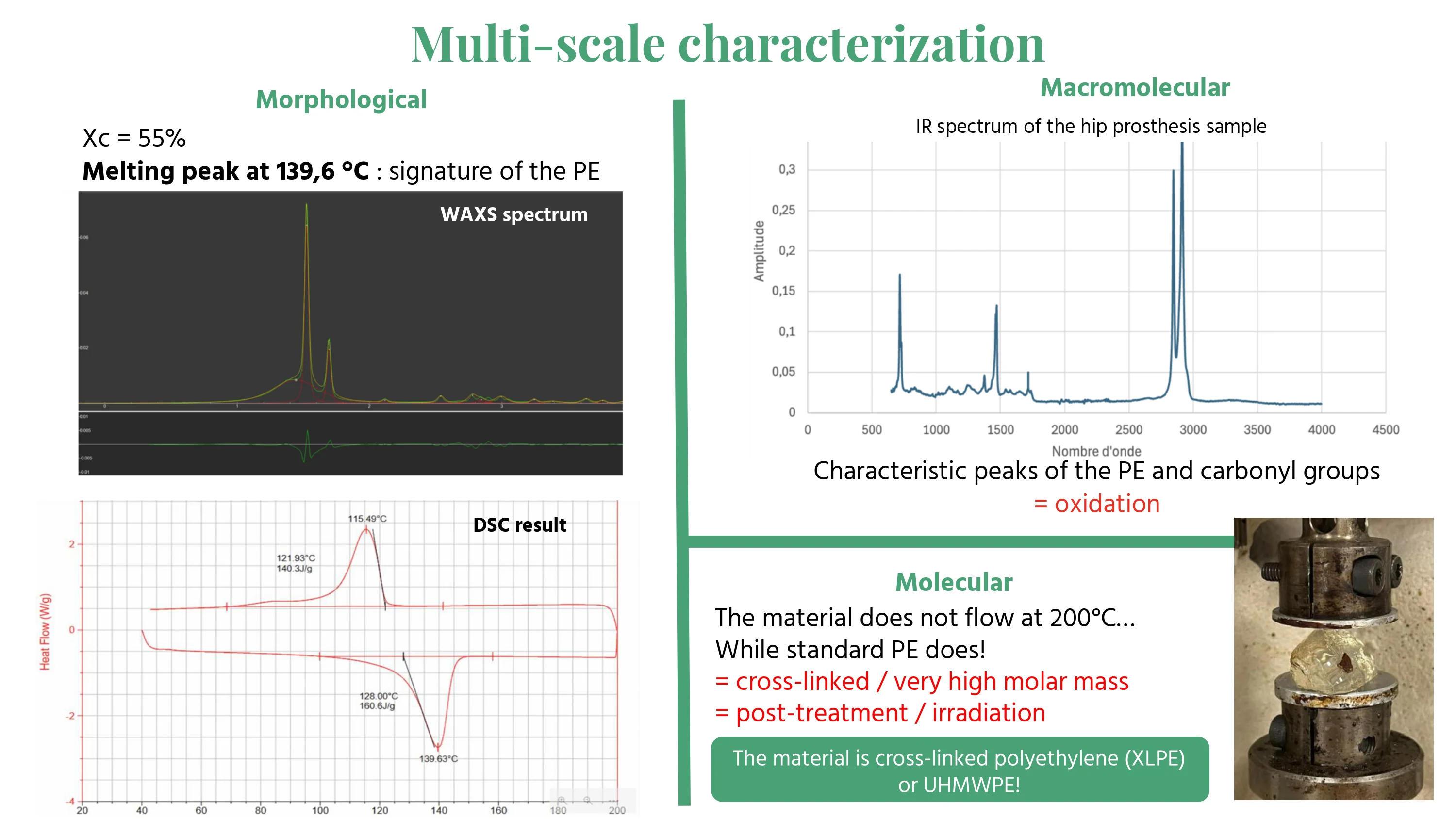

We carried out a multi‑scale material characterization on samples from an existing implant. Infrared spectroscopy confirmed a polyethylene matrix with carbonyl groups, indicating post‑processing cross‑linking. Rheological tests at 200 °C showed no melt flow, consistent with a cross‑linked polymer network. DSC and WAXS analyses revealed a 55 % crystalline structure, guiding our material choice.

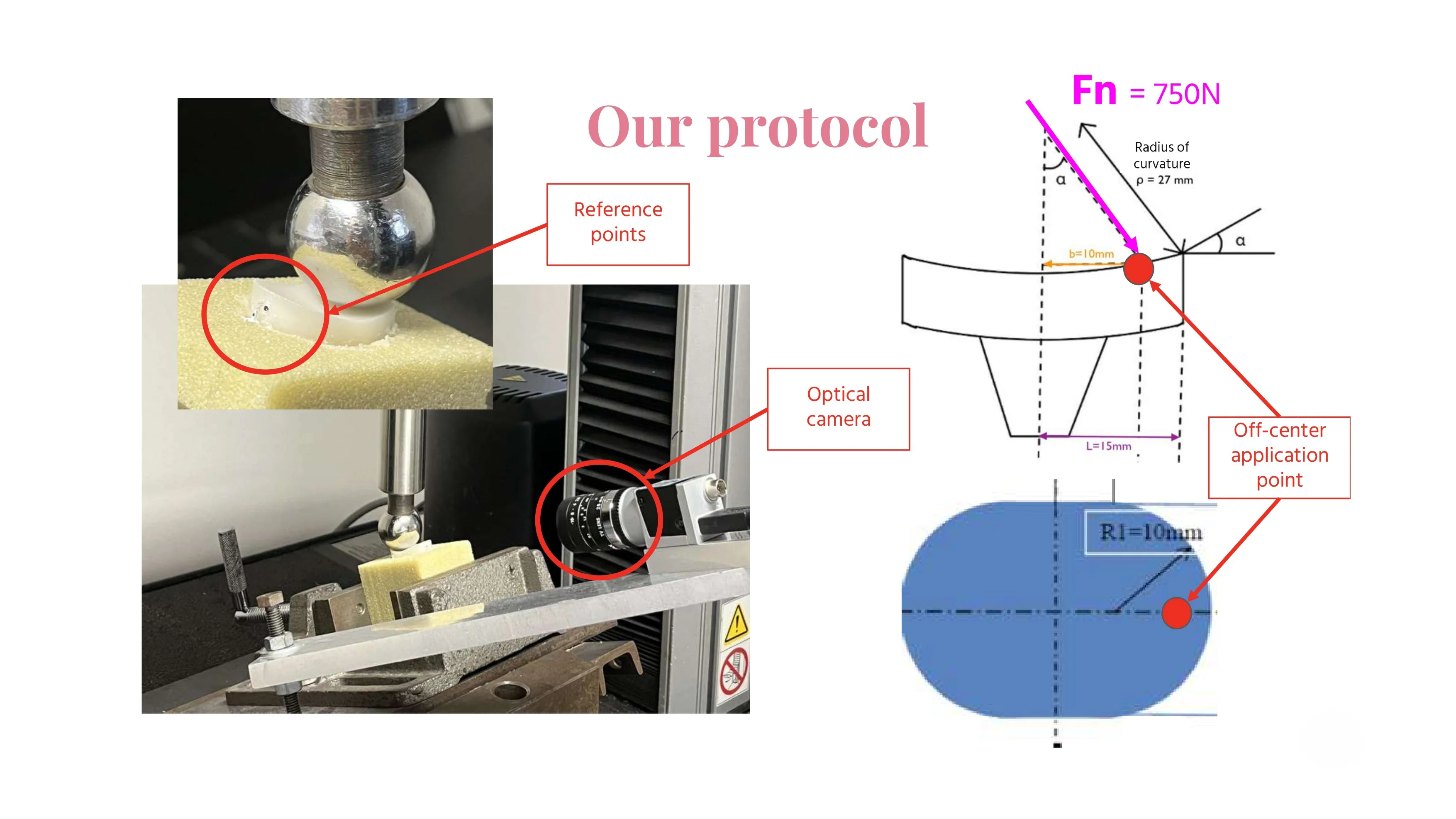

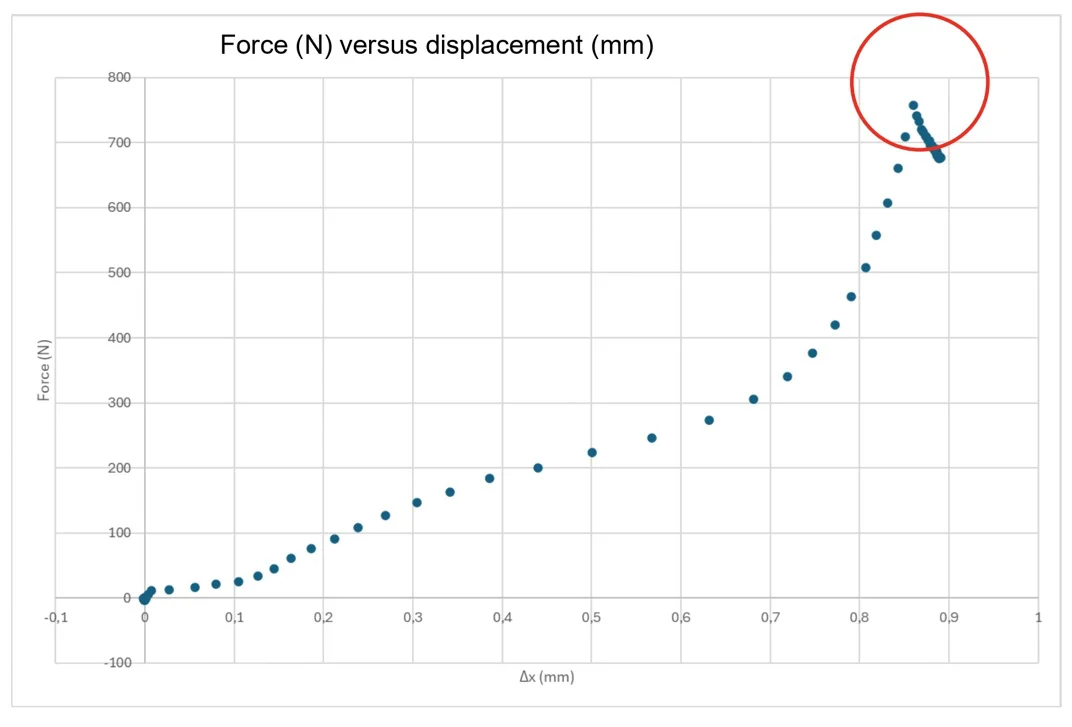

A dedicated test bench was designed to evaluate the fixation of a simplified glenoid component cemented into a synthetic bone block. A 750 N excentric load was applied on an inclined setup. Static tests showed no detectable motion, while cyclic loading revealed early micromotion and loosening after only 340 cycles, confirmed by a 0.86 mm gap in a post‑cycle static test. A final destructive test showed complete failure at approximately 1300 N, highlighting the sensitivity of the cement–implant interface and guiding design improvements.

CAD Design & FEM Validation

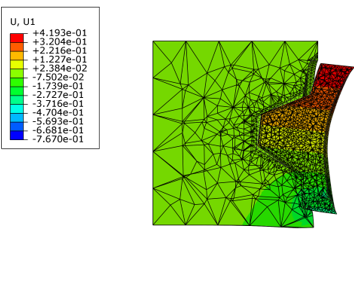

A simplified glenoid component was first modeled in CATIA and simulated in Abaqus. Material properties matched the test setup (bone substitute, PMMA cement, and a 3D‑printed polypropylene implant). The bone–cement interface was modeled as frictional (μ = 0.6) and the cement–implant interface as bonded.

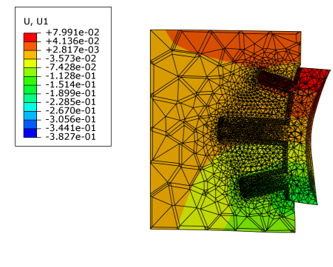

Based on these simulations, an optimized design with angled pegs and a perforated keel was developed. FEM results showed lower stresses and reduced micromotions, indicating improved stability.

Results & Conclusion

The optimized design achieved significantly lower micromotions and stress concentrations, confirming improved mechanical stability. Our validated FEM approach proved to be a reliable predictive tool, closely matching experimental results and guiding design choices.

This project strengthened my skills in CAD modeling, FEM simulation, and experimental validation. In parallel, I also performed a kinematic analysis lab, collecting motion data with dedicated sensors and processing it in MATLAB, further strengthening my skills in experimental data acquisition and signal analysis.

References

- Anglin, C., Wyss, U. P., & Pichora, D. R. (2000). Mechanical testing of shoulder prostheses and recommendations for glenoid design. Journal of Shoulder and Elbow Surgery, 9(4), 323–331.

- Geraldes, D. M., Hansen, U., & Amis, A. A. (2017). Parametric analysis of glenoid implant design and fixation type. Journal of Orthopaedic Research, 35(4), 775–784.

- Wahab, A. H. A., Kadir, M. R. A., Kamarul, T., Harun, M. N., & Syahrom, A. (2016). Analysis on stress and micromotion on various peg fixation at glenoid implant. Tribology – Materials, Surfaces & Interfaces, 10(1), 26–32.

- Wahab, A. H. A., Kadir, M. R. A., Harun, M. N., Kamarul, T., & Syahrom, A. (2017). Number of pegs influence focal stress distributions and micromotion in glenoid implants: A finite element study. Medical & Biological Engineering & Computing, 55(3), 439–447.

Acknowledgments

I would like to thank my teammates for their collaboration and dedication throughout this project: Romane Soulier, Felix Revillet, Hebin Yu as well as Prof. Diop and Prof. Maurel (ENSAM - IBHGC) for their guidance and constructive feedback during the design and testing phases.