Centrifugal Pump for Heart Failure

Objective

This project aimed to design a compact, efficient left ventricular assist device (LVAD) to improve quality of life for heart failure patients. The goal: deliver 3–12 L/min at up to 8 mH₂O head with minimal blood trauma and high hydraulic efficiency, balancing biomedical safety with real-world engineering constraints.

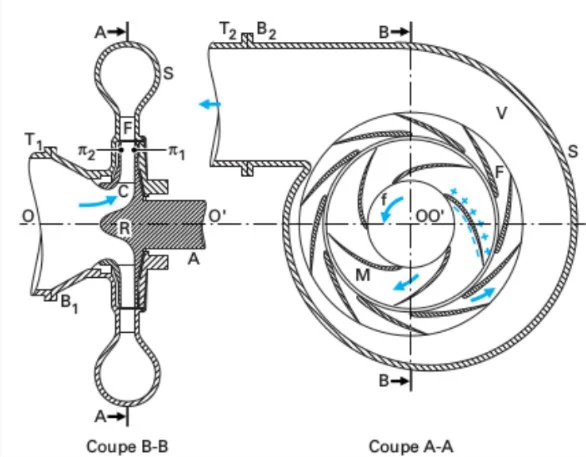

Preliminary Sizing

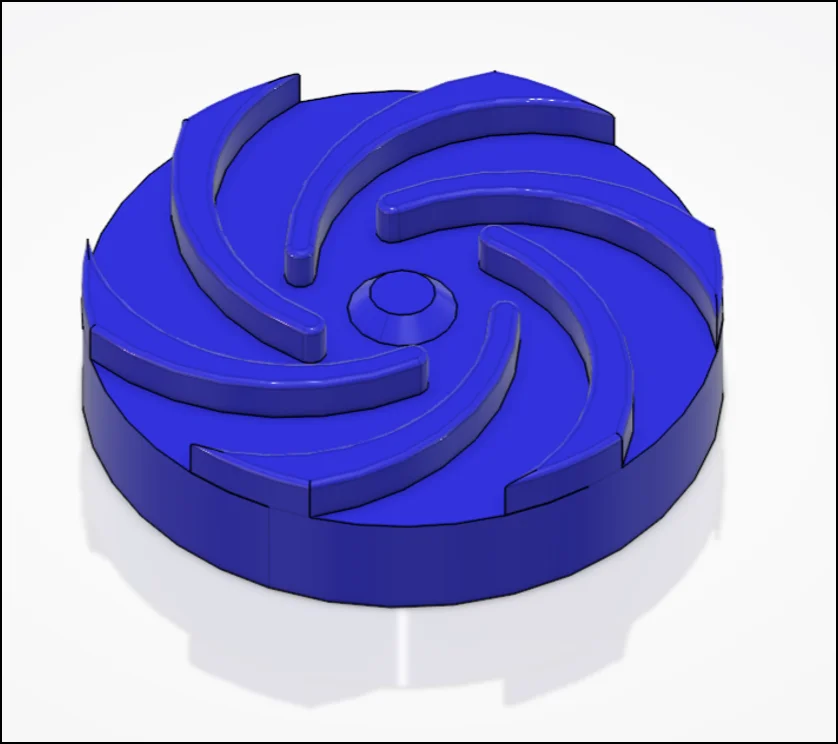

Automated calculations determined key dimensions: impeller diameter (Ø 42 mm), blade height (7.5 mm), and volute shape for the target 8 L/min at 4 mH₂O and 3 100 rpm. Design iterations balanced compactness, NPSH, and energy efficiency while avoiding cavitation risk.

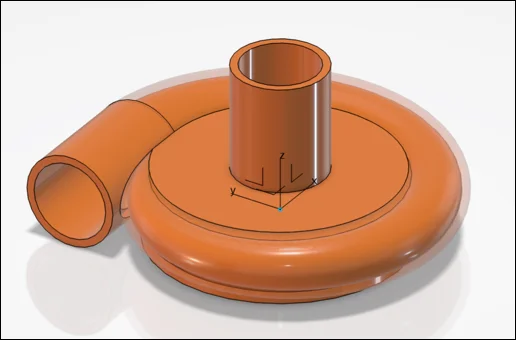

CAD & Mechanical Design

The impeller and volute were modeled in CATIA V5, with close attention to manufacturing feasibility and tolerance stacks. Blade curvature was optimized for both hydraulic performance and 3D printability, with defined clearances ensuring leak‑tight interfaces.

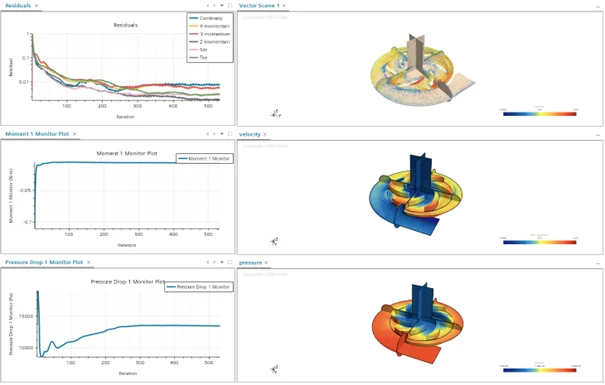

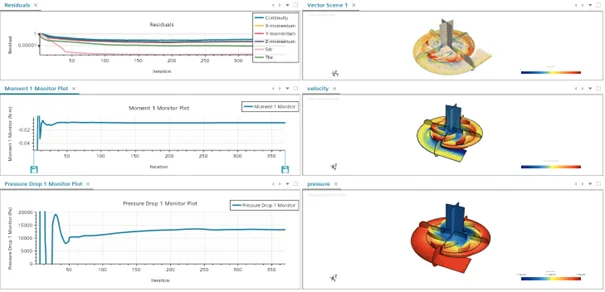

CFD Analysis

Steady-state simulations (Star-CCM+) validated expected flow and pressure at 3 100 rpm. A 3 mm polyhedral mesh with 5 prism layers captured wall effects; a k‑ω SST model resolved flow features.

Prototyping & Validation

PLA prototypes were printed and assembled to verify tolerances. While time did not allow for bench testing, the prototype was ready for flow validation.

Acknowledgments

I would like to thank my teammate Raphaël Fradin-Iberti for his collaboration and dedication throughout this project

as well as Prof. Ravelet, Prof. Kouidri (ENSAM – LIFSE), and Prof. Koutiri (ENSAM – PIMM) for their guidance and constructive feedback during the design and testing phases.