Aircraft Brake

Objective

The objective was to design a lightweight, compact brake system capable of decelerating a 685 kg light aircraft from 53 m/s at 4 m/s².

The assembly had to fit within a Ø 260 mm wheel and use a Ø 125 mm ventilated disc. We drafted a requirement sheet, compared over thirty concepts, and selected the most promising architecture for detailed design.

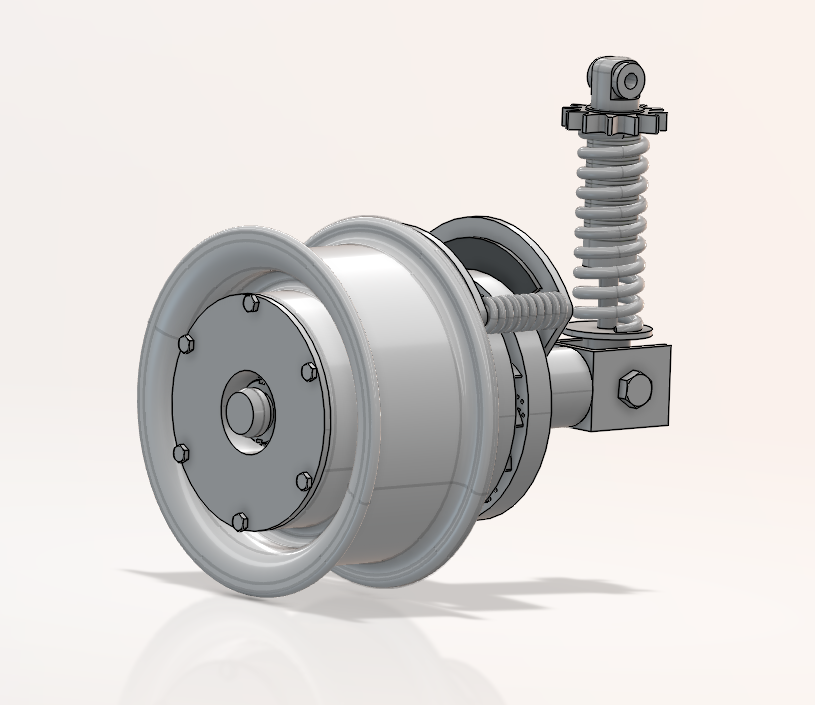

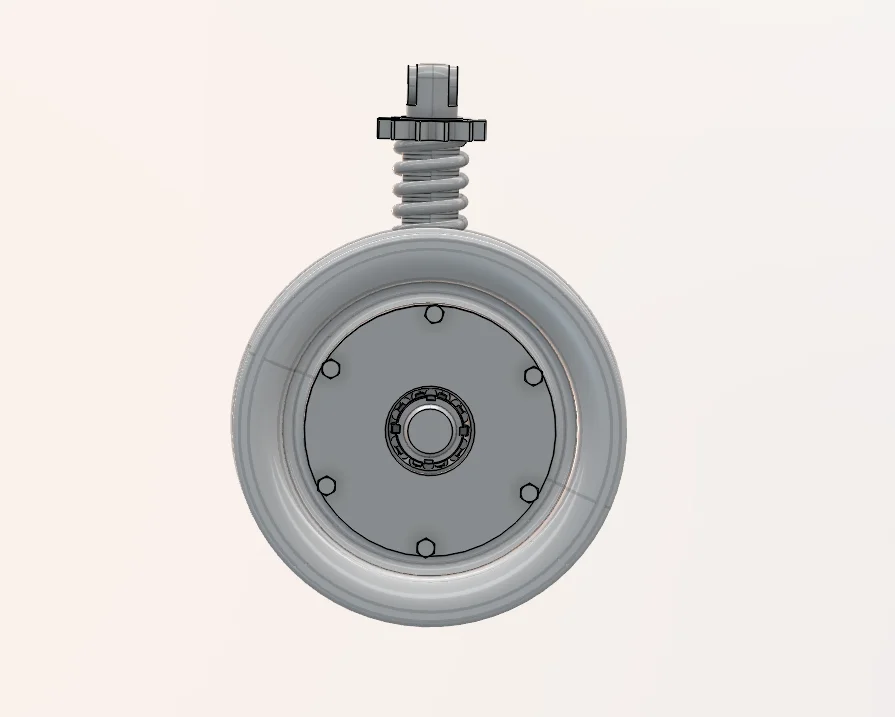

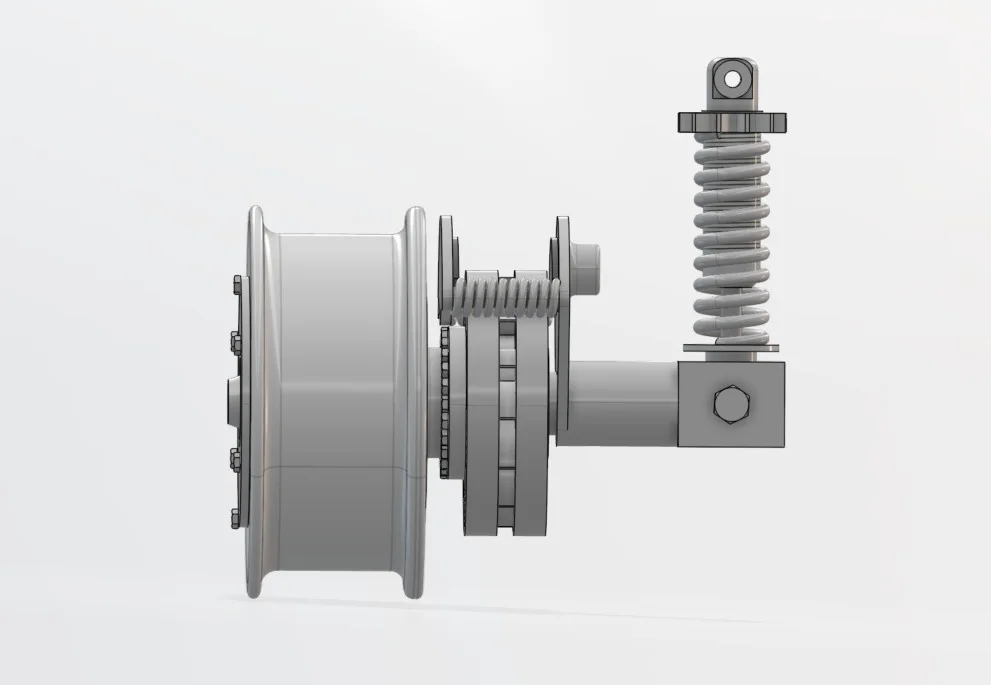

CAD Design

All parts were modeled in CATIA V5 with a parametric approach, allowing quick iterations and robust design updates.

Shaft, disc and carrier dimensions were iterated against bearing life (L10 > 5 000 h) and rotor inertia. The hub uses SNR 4T‑32004 X tapered‑roller bearings in O‑configuration, pre‑loaded via an M12 nut stack. Fastener groups (M5 × 0.8‑8.8) were checked per VDI 2230, and an H6/p6 interference fit prevents micro‑slip between hub and shaft.

CAD Model Highlights

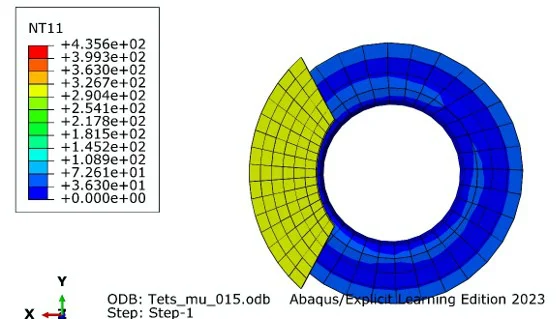

Finite Element Analysis

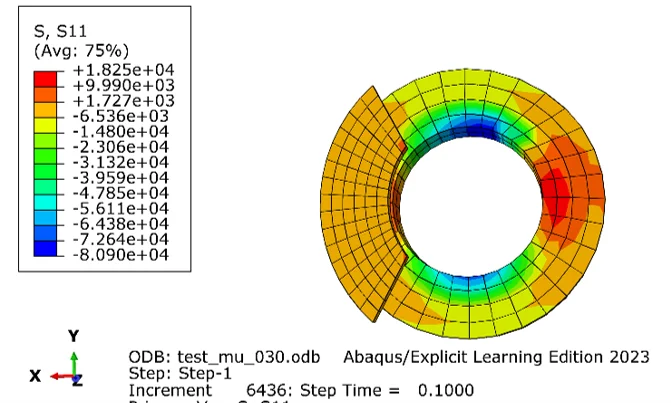

The assembly was exported to Abaqus Explicit and meshed with C3D8T elements. A coupled thermo‑mechanical step applied pad pressure (4 MPa) and convective cooling (h = 20 W/m²/K) for two friction levels (μ = 0.15 / 0.30).

In the nominal case, peak rotor temperature reached 436 °C and Von Mises stress 149 MPa, within 34NiCrMo16 service limits. Disc lateral deflection remained < 0.10 mm, ensuring pad clearance at full wear. The high‑grip case raised temperature to 551 °C but left stress unchanged, confirming robust safety margins.

Drafting

The finalized geometry was released as a full ISO 2‑D drawing set with: functional dimensions, GD&T, surface finishes (Ra ≤ 1.6 µm), heat treatments, torque tables, and BOM. Assembly notes reference the VDI 2230 pre‑load calculations and H6/p6 fit clearances.

Acknowledgments

I would like to thank my teammate Benedicte Maurel for her collaboration and dedication throughout this project as well as Prof. CAESTECKER (ENSAM) for his guidance and constructive feedback during the design.